Choosing the right marking technique for your product

Our team here at GSM Online Labels are frequently contacted by companies looking for a permanent marking solution on their products, this can be confusing as there are many factors to be considered including material, budget, and environment. The below blog will help outline the basics between Dot Peen Marking & Laser Marking.

The basic difference between Dot Peen Marking and Laser Marking

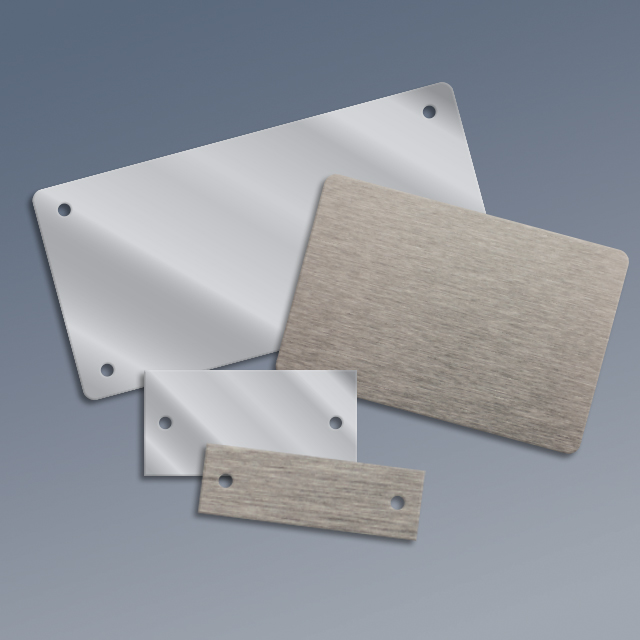

Dot Peen Marking is a technique using a pinned tip made from rigid material such as carbide to indent the desired material, whether marking out text or numbering the pin head creates closely spaced dots to form the detail. Dot Peen Marking is often used for marking dense materials such as stainless steel, aluminium, and hard plastics. The process used to create the detail is limited to coding and identification, but a great option for harsh environments where the plate is subject to industrial cleaning, abrasions etc giving you peace of mind it is made to last.

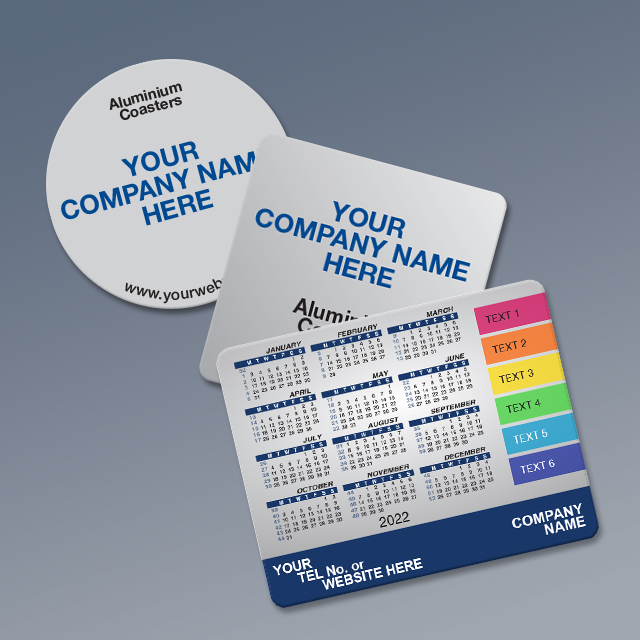

Fibre Laser Marking unlike the dot peen is non-impact, the substrate simply needs to be placed under the laser at a focal height depended on the chosen depth of the marking. The laser then etches the material without the need of blunt force, this providing a quality marking and the ability to provide greater marking versatility and visibility giving capability to form more intricate details such as logos, artwork. The laser also creates easy scanning of 2D codes due to the contrast the laser creates when Laser Marking.

Want to add a bit of colour?

Here at GSM Online Labels, we can offer either natural aluminium & stainless steel or colour printed anodised aluminium. If you are looking for something bold or to be noticed from afar, we can treat aluminium by electrically charging the metal which causes the ‘pores’ of the metal to open up, thus allowing us to print coloured ink into the ‘pores’ the of metal. The aluminium is then sealed to lock in the ink beneath the anodic layer, this creating a durable barrier for ink.

Dot Peen Marking onto deeply coloured anodised aluminium produce the perfect contrast. When using this method, the indentations expose the natural silver metal underneath creating this contrast between the coloured ink and natural silver.

If you require more intricate and finer details on your coloured plates including your logo or artwork, the Fibre Laser Marker is ideal giving you a flawless finish with durability and confidence it can endure all extreme conditions.

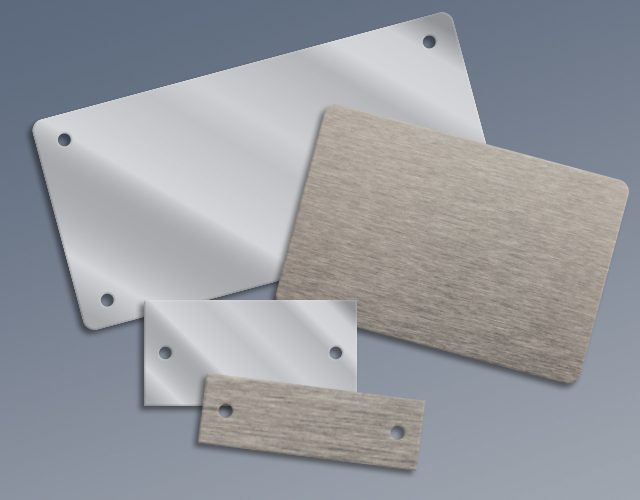

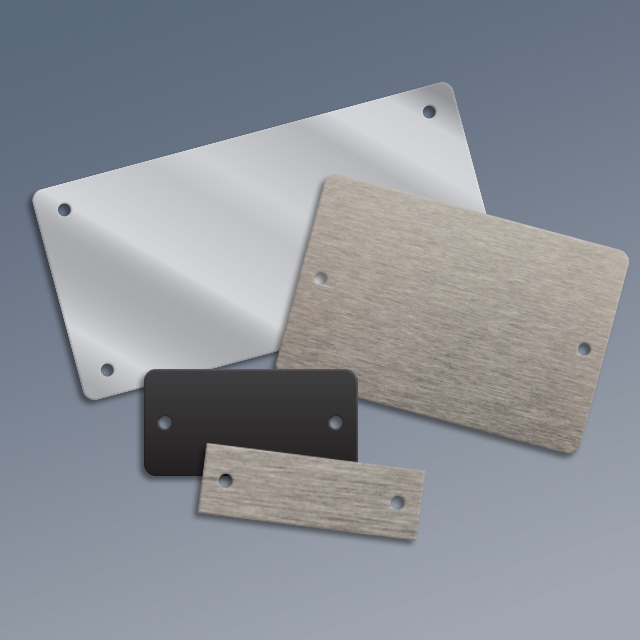

Click here to read more about our Laser Marking and Dot Peen blanks and to view the full range and options available.

If you cannot see the size or requirements you need please call our team and we can arrange a bespoke quotation.