304 VS 316 Stainless Steel Labels

GSM Online Label Sales have manufactured labels using both 304 and 316 stainless steel for many years.

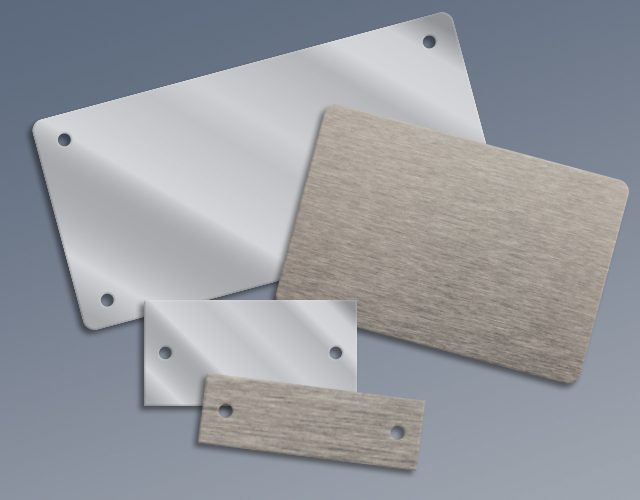

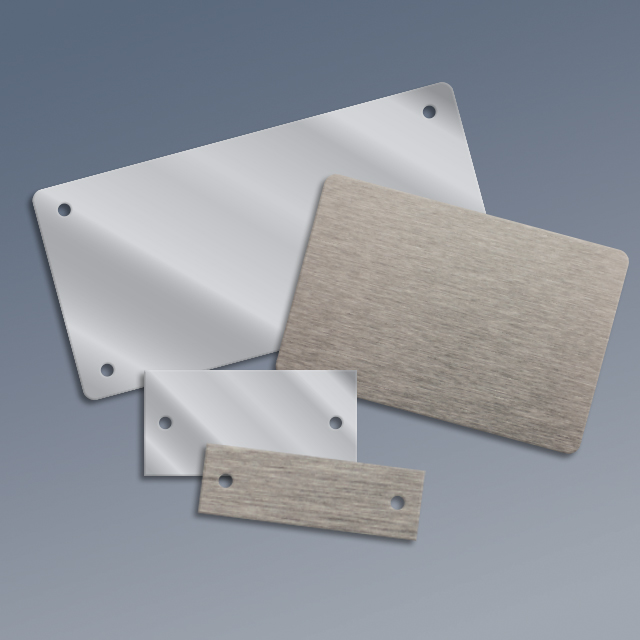

We provide natural 304 and 316 stainless steel blank labels for customers to purchase and mark in house. Although it is difficult to visibly identify differences between the 2, they do exist and it could be the reason one will be chosen in a given environment over the other.

Whilst both make extremely durable labels, there are factors and properties that they have that differ, meaning that one may be more durable than the other for certain applications or in a particular environment.

316 stainless steel contains a minimum of 2.0% molybdenum which makes it more corrosion resistant metal. 316 stainless steels performance when it comes to chlorinated applications or exposure to salt, is superior. The combination of these two benefits to 316 stainless steel means that it is ideal for use in industries such as petrochemical and offshore.

304 stainless steel has a higher melting point to 316 meaning that it may be better suited to a high temperature environment such as use in ovens or furnaces.

Marking in House

When using blank stainless steel labels for in house marking, both 304 and 316 can be engraved by dot peen marking, laser marking or engraving the plates. These methods are durable because in one way or another they remove a layer off the surface of the steel which leaves a permanent mark that is resistant to some of the harshest environments.

We have various sizes available of our stainless steel blanks. These are then customisable by what fixing method is used; self-adhesive and/or fixing holes and whether square or radius corners are required. Various finishes are available and include; 240 grit (brushed), 2B (matt) or bright annealed finish (shiny) finishes.

View our range of sizes here.